A recent virtual field trip took us behind the scenes at T. Marzetti, where we learned about the world of dressings, dips, and sauces. Marzetti began years ago as a popular restaurant, but transitioned to making dressings. The Innovation Center in Lewis Center houses eight labs and about 80 employees.

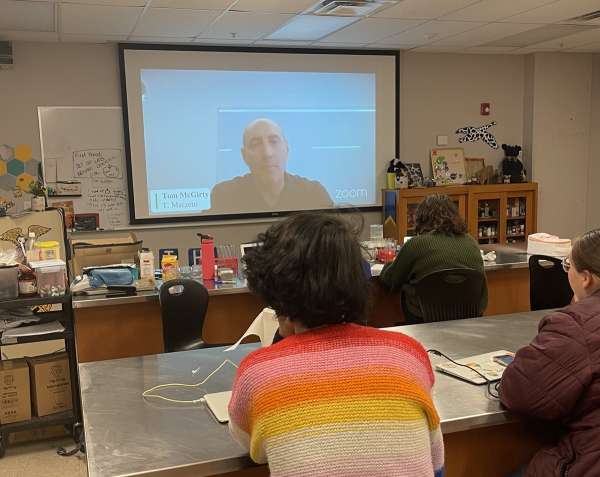

Tom McGirty, Vice President- Research & Design/Dressings, Dips, and Sauces, talked to the audience about the science behind salad dressings. The company uses a lot of soybean oil—200 million pounds each year—for its popular dressings. McGirty compared creating a dressing to building a house. “It has to have a good foundation. We look at how to make it physically, chemically, and microbiologically stable, as well as how to make it taste good.”

Jamie Hannen, Associate Principal Scientist in Research & Design, led the tour and explained about the work done there. Designing a new formulation must take into consideration things such as desired flavor, consumer expectation, application and desired appearance, desired storage and shelf life, cost target, and nutritional parameters.

The main components of dressing are oil, water, acid, sweetness, and saltiness. A dressing is an emulsion, a mixture of two or more liquids where one is present as droplets distributed throughout the other. To give an example, Melanie made ranch dressing in the lab.

The process began by mixing the dry buttermilk, garlic, and onion powders with water and letting them hydrate. The order of ingredient addition is important to avoid clumping. Xanthan gum is added with soybean oil to thicken the mixture, and then eggs for emulsification. Next, sugar and salt are added, and lastly, parsley and black pepper for taste and appearance.

The finished dressing then went to the Quality Assurance lab for testing. Isaac checked for the percent of acid and salt in the formula. pH should be within a certain range. Density is tested to check weight of product for transportation. A viscosity test measures thickness by seeing how far the sample travels down an equipment slope in 30 seconds. All of these tests make sure the product is safe for consumers and meets government regulations.

Hannen gave an overview of the careers related to the food science industry: research and design, chemistry, food safety and microbiology, packaging engineering, nutrition, processing physics, regulatory, sensory and market research, business, quality assurance, and processing. “We hope that this tour will inspire students to consider these careers,” Hannen said.

Share this virtual field trip with your students! The recording is available here.

Share this